JTVG-B Explosion-proof lever hoist

Product Overview

The JTVG-B Lever Hoist is specifically designed for safe lifting and lowering in hazardous environments where explosive gas or dust may exist. Certified to Ex II 2 GD standards, this hoist meets the highest safety requirements under ATEX Directive 2014/34/EU and Machinery Directive 2006/42/EC. Available in multiple capacities, it is ideal for offshore, oil & gas, mining, chemical, and marine operations.

Product Features

-

ATEX Certified: Complies with Ex II 2 GD c IIC T4 IIIC T135°C standards for explosion protection

-

Wider Operating Temperature: Safe operation from -40°C to +80°C (optionally up to -60°C)

-

Corrosion Resistant: All exposed parts are coated or made of stainless steel, suited for marine or harsh environments

-

Special Coated Housing: Anti-static powder-coated body with sealed brake chamber

-

Copper-Plated Parts: Hooks, load chain guides, hand wheels, and fixings are copper-plated for spark prevention

-

Stainless Steel Options: Hand chain, load chain, fixings, and fasteners available in stainless steel

-

Available with Overload Protection: Optional clutch system for added lifting safety

-

Customizable Lift Height & Capacity: Flexible configurations based on work site needs

-

Marine Friction Discs: Specially designed brake discs for offshore or damp locations

Application Scenarios

-

Oil and Gas fields

-

Petrochemical and refinery zones

-

Offshore marine platforms

-

Chemical processing facilities

-

Underground mining zones

-

Any ATEX classified Zone 1 or Zone 2 environment

Standard

BS EN 13157

ANSI/ASME

B30.16

AS 1418.2

JB/T 7334

CNEX 18.5240

isi 2015

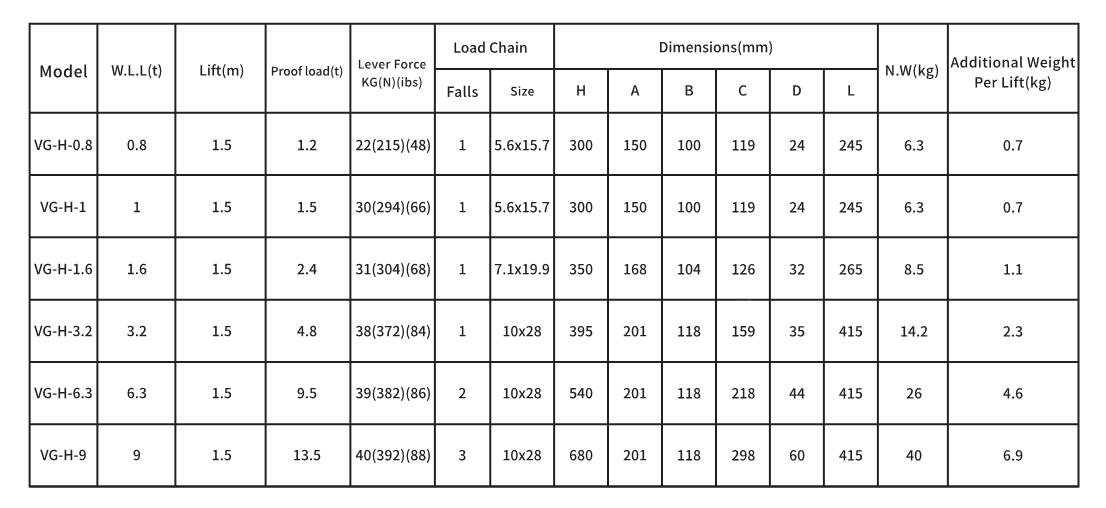

Product selection

1. Overload limiter 2.100 grade load chain

Application industry

Explosion-proof lever hoist is widely used in petroleum, chemical, gas, textile, pharmaceutical, storage and transportation, coal mines and other high temperature, high dust, corrosive industries, for the equipment maintenance and installation of the flammable and explosive places. Can be used alone, can also be used with explosion-proof monorail car.