How to Choose the Right Electric Hoist: Understanding Duty Classifications

2025-07-14 200 FOLLOW Jentan Machinery | www.jentanhoist.com

When selecting an electric hoist, lifting capacity and speed are important—but not enough. One of the most critical factors is the duty classification, also known as working duty or duty cycle. It defines how often and under what conditions the hoist can operate safely and efficiently.

What Is Duty Classification?

Duty classification refers to the frequency of operation, load intensity, and duration of use. Hoists used for light maintenance work will have different duty ratings than those used on fast-paced production lines.

A mismatch between the hoist's duty class and actual use can lead to:

-

Overheating

-

Gear and brake damage

-

Shortened service life

-

Unexpected downtime

Why It Matters

Choosing the wrong duty classification is one of the most common causes of hoist failure. Even a strong hoist can wear out quickly if it’s used beyond its rated cycle.

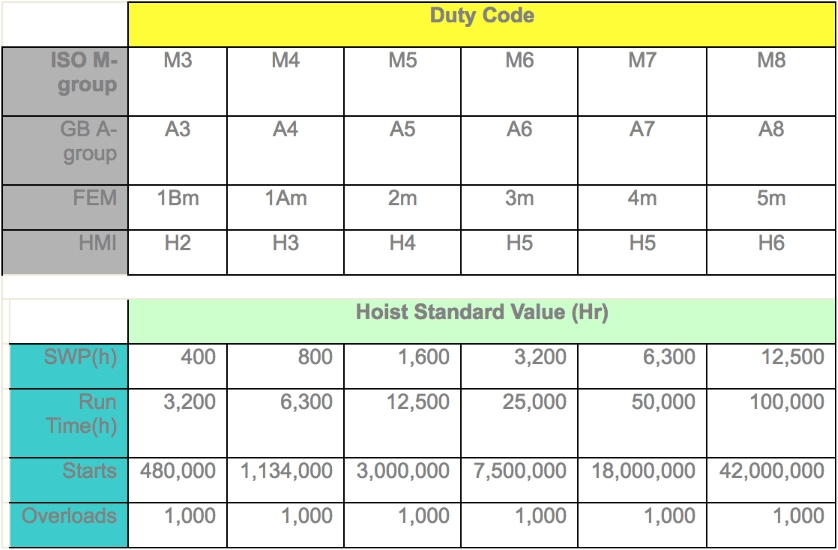

Main International Standards for Duty Class

| Standard | Classification | Typical Use | Working Hours/Day | Load Spectrum |

|---|---|---|---|---|

| ISO 4301 | M1 to M8 | From very light to very heavy duty | 0.5–24 hrs | Light to severe |

| FEM 9.511 | 1Bm, 1Am, 2m, 3m | Light to intensive operation | 1–20 hrs | 25% to 100% load |

| ASME HST-1 | H1, H2, H3, H4, H5 | Maintenance to high production use | ≤ 24 hrs | Occasional to frequent |

Examples:

-

FEM 1Bm (ISO M3 / ASME H2): Occasional use, maintenance hoists.

-

FEM 2m (ISO M5 / ASME H4): Frequent lifting in production lines.

-

FEM 3m (ISO M6 / ASME H5): Intensive, 24/7 industrial operations.

How to Match Your Application

-

Check Lifting Frequency

-

Occasional (few times/day)? Choose lower duty like M3 / 1Bm.

-

Continuous use (production)? Go for M5-M6 / 2m-3m.

-

For production use, consider our JTEC-F Electric Chain Hoist with Frequency Inverter rated for FEM 2m duty.

-

-

Check Load Variation

-

Mostly partial load? Lower classification is fine.

-

Frequent full capacity lifts? Choose higher duty level.

-

-

Operating Time per Day

-

Short-term use? ISO M3–M4 (1Bm–1Am)

-

Long shifts or round-the-clock? M5–M6 (2m–3m)

-

-

Environment Conditions

-

Hot, dusty or corrosive? Go one class higher than planned.

-

Key Takeaways

-

Duty classification is just as important as load capacity.

-

Over-specifying increases cost, under-specifying risks safety.

-

Know your work environment and match with the correct rating.